Exploring the Durability and Versatility of Composite Strapping in Manufacturing

In today’s fast-paced manufacturing world, efficient packaging plays a critical role in ensuring product safety, reducing costs, and enhancing the overall sustainability of operations. Among the many materials used for packaging, composite strapping has emerged as a highly effective solution for industries worldwide. Combining strength, flexibility, and environmental advantages, composite strapping offers manufacturers a durable and versatile option for securing products during transit and storage. This article explores the durability and versatility of composite strapping and why it is increasingly being favored in manufacturing settings.

What is Composite Strapping?

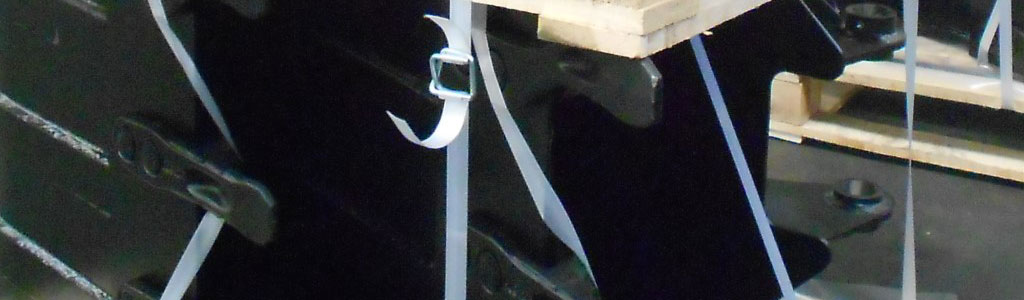

Composite strapping is a type of industrial-grade packaging strap that is typically made from a blend of synthetic fibers, such as polyester or polypropylene, and a plastic coating. This combination provides the strap with both flexibility and strength. The synthetic fibers add tensile strength, while the plastic coating offers durability and protection against abrasions, moisture, and UV damage. Composite strapping is often used in industries that require heavy-duty packaging, such as logistics, manufacturing, construction, and even recycling.

Unlike traditional metal strapping, composite strapping is lighter and more flexible, making it easier to handle and apply. This has made it an increasingly popular choice for manufacturers who need to secure their products while reducing the risks associated with using more rigid materials.

Durability of Composite Strapping

One of the most notable advantages of composite strapping is its superior durability. Whether it’s securing goods for transport or holding large bundles of materials in place during storage, composite strapping is designed to withstand a range of tough conditions. Here’s a closer look at some of the factors that contribute to its durability:

1. **Tensile Strength**

Composite strapping boasts impressive tensile strength, which refers to its ability to endure tension without breaking. Made from high-strength polyester fibers, composite strapping can carry heavy loads without compromising its structural integrity. This makes it ideal for industries like construction, manufacturing, and logistics, where products need to be transported and stored safely under substantial stress.

2. **Resistance to Weather and Environmental Factors**

One of the significant advantages of composite strapping is its resistance to environmental factors such as moisture, UV radiation, and extreme temperatures. While metal straps can rust or corrode when exposed to water or humidity, composite strapping remains unaffected by moisture. Additionally, its UV-resistant coating ensures that the strap won’t degrade or lose strength when exposed to sunlight. This durability in varying weather conditions makes composite strapping suitable for outdoor use or in climates with extreme weather.

3. **Impact and Abrasion Resistance**

The durable coating on composite strapping gives it a high degree of resistance to abrasion and impact, which are common risks during transport and handling. This means that composite strapping will not easily break or fray, even when exposed to rough surfaces or heavy contact. As a result, it ensures the security of the packaged products and reduces the likelihood of damage during shipping.

4. **Long-Term Performance**

Composite strapping is designed for long-term performance, making it an excellent investment for manufacturers. Unlike metal straps, which can become brittle over time, composite strapping maintains its flexibility and strength throughout its lifespan. Manufacturers don’t need to worry about frequent replacements, which helps to reduce overall maintenance costs.

Versatility of Composite Strapping

While composite strapping’s durability is certainly impressive, its versatility is another key reason why it has gained widespread adoption in manufacturing. The following are some of the ways composite strapping can be used across various industries:

1. **Flexible Applications**

Composite strapping can be used across a wide range of industries and for various applications. It is commonly used in securing large or heavy products during transport, such as bundles of steel, lumber, or construction materials. However, composite strapping is also used in securing smaller packages, such as boxes, cartons, and even delicate items. Its flexibility allows it to adapt to different sizes and shapes of products, making it a one-size-fits-all solution for diverse packaging needs.

2. **Lightweight and Easy to Handle**

Another advantage of composite strapping is its light weight. Unlike metal straps, which are often cumbersome and require special tools for application, composite strapping is lightweight, easy to maneuver, and can be applied with minimal effort. This makes it ideal for manufacturers who need to quickly secure products without investing in expensive, specialized equipment. Additionally, because it is easy to handle, it reduces the risk of injury and worker fatigue during the packaging process.

3. **Eco-Friendly Option**

With an increasing focus on sustainability, composite strapping is gaining popularity as an eco-friendly alternative to traditional packaging materials. Many composite straps are made from recyclable materials and are designed to be reusable. As more companies look for ways to reduce their carbon footprint, composite strapping provides an effective solution that aligns with sustainability goals. By reducing the need for metal or other non-renewable packaging materials, manufacturers can contribute to a greener supply chain.

4. **Cost-Effective**

Cost-efficiency is a driving factor for any business decision, and composite strapping offers a competitive edge in this area. Not only is it more affordable than metal strapping, but its durability and reusability also contribute to reduced packaging costs in the long term. The lighter weight of composite strapping can also reduce shipping costs, further contributing to a more cost-effective packaging solution.

5. **Customizable for Specific Needs**

Composite strapping is available in various sizes, thicknesses, and strengths, allowing manufacturers to choose the best type for their specific packaging needs. This level of customization ensures that businesses can use composite strapping for a wide array of products, from lightweight consumer goods to heavy industrial equipment. Manufacturers can also opt for color-coded straps, providing an easy way to identify different product categories or ensure compliance with safety standards.

Conclusion

Composite strapping is a highly durable and versatile packaging material that continues to gain traction in the manufacturing industry. Its exceptional tensile strength, resistance to environmental factors, and impact resistance make it an ideal choice for securing products during transit and storage. In addition, its lightweight nature, cost-effectiveness, and eco-friendly properties make it a versatile solution that can be used across a variety of industries and applications.

As manufacturers strive to optimize their supply chain operations and meet sustainability goals, composite strapping is becoming an indispensable tool in packaging solutions. With its combination of durability and flexibility, composite strapping is poised to remain a top choice for manufacturers seeking reliable and efficient packaging materials for years to come.