Cord Lashing Strap – Durable and Safe Packaging Solution

Introduction

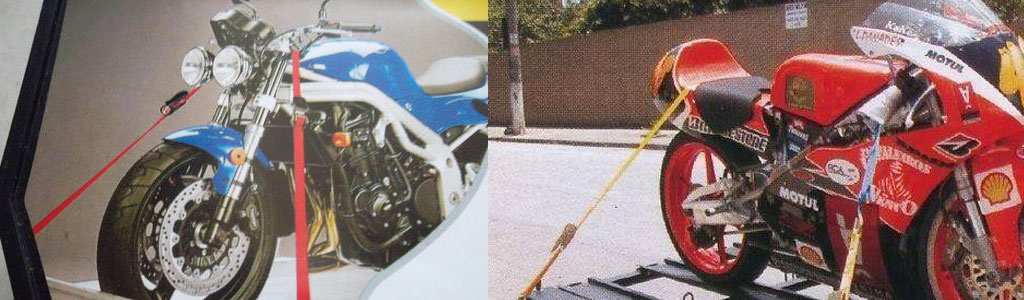

In today's world of logistics and transportation, ensuring the safety of cargo during transit is crucial. One of the best solutions available on the market is the Cord Lashing Strap, which combines high strength with flexibility and ease of use. In this article, we will explore why the Cord Lashing Strap is an ideal choice for packaging and securing goods, its advantages, and its applications.

What is a Cord Lashing Strap?

A Cord Lashing Strap is a high-quality strapping material made of strong polyester fibers, woven together to provide excellent resistance to tension and breakage. Thanks to its unique structure, this strap is flexible yet highly durable, making it a great alternative to steel and plastic strapping materials.

Advantages of Cord Lashing Strap

1. High Tensile Strength

Cord Lashing Strap can withstand heavy loads, making it an ideal solution for securing heavy cargo such as wood, steel, or industrial machinery. Due to the use of high-quality polyester fibers, this strap does not break or weaken even in tough transport conditions.

2. Flexibility and Safety

Unlike steel straps, which can be sharp and hazardous, the Cord Lashing Strap is safe for operators. It has no sharp edges and does not cause injuries, significantly reducing the risk of accidents during packaging and transportation.

3. Weather Resistance

One of the greatest advantages of the Cord Lashing Strap is its resistance to moisture, UV radiation, and temperature changes. This makes it suitable for use in various climatic conditions without the risk of degradation or loss of strength.

4. Lightweight and Easy to Use

The Cord Lashing Strap is significantly lighter than steel strapping, which makes it easier to transport and apply. It can be used manually with simple tensioners and buckles, making it a convenient solution for various industries.

5. Cost-Effectiveness

Due to its durability and reusability, the Cord Lashing Strap is a more economical option than other strapping materials. Additionally, its lightweight nature helps reduce transportation and storage costs.

Applications of Cord Lashing Strap

The Cord Lashing Strap is widely used across different industries, including:

-Transport and Logistics – Securing palletized cargo, containers, and truck loads.

-Wood and Construction Industry – Bundling wooden planks, panels, bricks, and construction materials.

-Metal Industry – Stabilizing and securing steel products, pipes, and profiles.

-Agriculture and Export – Packaging and securing agricultural products, grain sacks, and fertilizers.

-Chemical Industry – Fastening barrels and containers with chemical substances.

How to Properly Use a Cord Lashing Strap?

To ensure maximum safety and efficiency of the Cord Lashing Strap, follow these basic usage guidelines:

1.Choose the Right Width and Strength – The selection of the strap should match the weight and type of cargo.

2.Use the Correct Accessories – The strap should be secured using special buckles that ensure stability.

3.Proper Tensioning – The strap should be adequately tightened to provide maximum stability without damaging the cargo.

4.Inspection and Maintenance – Regularly checking the condition of the strap and buckles helps avoid issues related to wear and tear.

Comparison of Cord Lashing Strap with Other Strapping Materials

Cord Lashing Strap vs. Steel Strapping

-The Cord Lashing Strap is safer to use because it has no sharp edges.

-It is resistant to corrosion and moisture, unlike steel strapping.

-It is more flexible and better absorbs shocks during transportation.

Cord Lashing Strap vs. PP and PET Straps

-It is stronger and more flexible than polypropylene (PP) and polyester (PET) straps.

-It is better suited for heavy cargo as it does not break or lose its properties under tension.

-It is more resistant to weather conditions than standard plastic straps.

Conclusion

The Cord Lashing Strap is a versatile and reliable packaging solution that combines high strength, flexibility, and safety. Its resistance to harsh environmental conditions and ease of application make it widely used in many industries. Its advantages make it an excellent alternative to traditional steel and plastic strapping, ensuring effective and cost-efficient cargo securing during transportation and storage.

If you are looking for a durable and efficient solution for bundling and securing loads, the Cord Lashing Strap is the perfect choice!